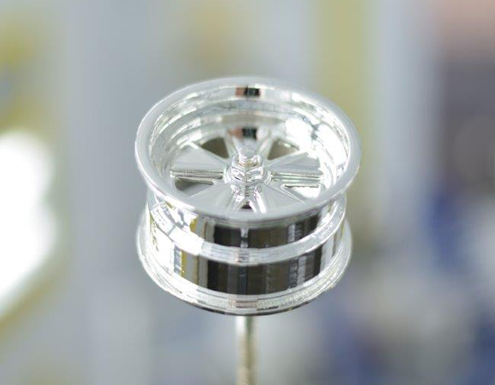

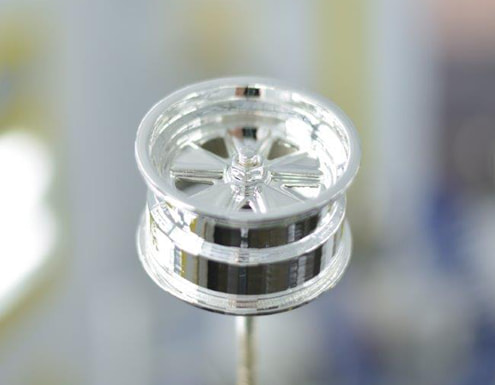

Our process begins with a thorough assessment of your chrome parts. We carefully inspect each component for corrosion, pitting, and scratches. Our skilled technicians use advanced techniques to strip away old plating and repair any underlying damage. We then apply a high- quality chrome spray that enhances durability and ensures a mirror-like finish.

About Chromefinish

Chrome spray can be used over any surface that can be primed.

We have successfully chromed over wood, glass, plastics, carbon fibre, 3D prints, all metals!

We can Chrome Spray Almost Anything!

call us nowTake a Look at our Chrome Spraying videos

Chrome spraying services is the only viable alternative to traditional chroming, and it has a couple of big advantages: it costs less, and it is also considerably better for the environment.

chrome tinting

Our specialised process that involves applying a thin layer of metallic or reflective coating to a surface to create a sleek, mirror-like finish. This technique is widely used for both aesthetic and functional purposes, particularly in automotive, architectural, and industrial applications.

Chrome spraying

Chrome spraying begins with surface preparation, involving cleaning, sanding, and priming to enhance the final chrome effect. Next is the spray coating process, where precision chemical spraying is performed using specialised equipment.

extras

Key benefits of our chrome spraying services:

Enviromentally friendly: Uses fewer hazardous chemicals compared to traditional chrome plating.

Versatility: Works on non-metal surfaces and complex shapes that would be difficult to plate traditionally.

Cost-effective: Generally, less costly and labour intensive that electroplating.

frequently

asked questions

Cleaning removes dust, oils, and contaminants that could interfere with the adhesion of the chrome effect.

get in touchColour tints are applied during the initial chroming process, enabling the creation of unique shades and effects.

get in touchChrome restoration is the process of repairing and refinishing chrome components to restore their original shine and brilliance. The process starts with an assessment of the chrome parts, followed by cleaning, repairing damage, and re-plating to ensure a flawless, mirror-like finish.

get in touchChrome restoration repairs dull or damaged parts, enhances durability, and restores the timeless elegance of your vehicle.

get in touchIt is created using two chemicals that react when atomised, forming silver nitrate, which gives the chrome effect.

get in touchThe topcoat protects the finish from corrosion, scratches, and oxidation, while enhancing its shine. The coated surface is cured in a high-performance oven to ensure the topcoat hardens and bonds effectively.

get in touchSprayed helmet

Chromefinish process

01

01& Sanitise

02

02Surface

03

03Primer

04

04Chrome

05

05Process

latest blog posts

Follow us @chrome.finish

clients we work with

more

more